INSERTING WITH

BOWE SYSTEC

###BREADCRUMB###

Secure and fast inserting with BOWE SYSTEC inserters for transactional applications or direct mail! Printing and inserting applications are becoming increasingly specific, with more and more variants, whilst individual jobs are getting smaller and the demands placed on production all the greater. As experts in document and post processing, we offer a comprehensive range of inserting machines across a broad performance spectrum – from simple, basic machines to smart, fully automated, high-performance systems for high volume mailings and the most demanding of applications. Whether transactional or direct mailing, high-performance inserting machines from BOWE SYSTEC guarantee secure and economical processing of your documents. Numerous features for automating up- or downstream stages and finishing offer modern print and mail processing centers, lettershops or direct mail service providers the flexibility they need to be fit for whatever the future brings. Take advantage of our years of experience as a mailroom specialist and discover our innovative solutions for inserting and mailing letters or promotional material together with the total control provided by our intuitive app-based software. The smart way in which the systems can be networked and intuitively controlled paves the way to the fully automated and highly flexible mail production center of tomorrow. Interfacing to a Warehouse Management System as well as the integration of further automation technologies also opens up entirely new possibilities for the automation and enhanced efficiency of your mail production center.

Production

PLANNING, CONSULTING AND SUPPORT: CUSTOMIZED SOLUTIONS THAT EXACTLY FIT TO YOUR NEEDS

###BREADCRUMB###

BOWE SYSTEC INSERTERS: INSERTING MADE PERFECT

###BREADCRUMB###

Assembling and folding documents, feeding enclosures, folding and enclosing letters or mailings and preparing the filled and finished letter for franking and distribution by the mail. All this may sound simple and straightforward but automated inserting during post-processing is most definitely not. Inserting systems for the modern mailroom actually involve highly automated processes designed to deliver reliability and efficiency whilst satisfying the highest security requirements. This ensures that all the components of a personally addressed letter together with individual enclosures and the envelope reach precisely the right recipient in their entirety. And that’s before considering the vast range of different formats and materials that the automated inserter must be able to process.

The performance and capabilities of the inserters produced by the Augsburg automation specialists BOWE SYSTEC cover the full spectrum of envelope insertion for very different mail processing applications and volumes. The portfolio includes flexible solutions for the enveloping of direct mail, statements, catalogs, brochures, conventional daily post, insurance policies and much more – from simple, basic inserting systems to smart, fully automated, high-performance systems for high production volumes and the most demanding of applications. Document and post processing that leaves nothing to be desired.

THE FUSION SERIES INSERTING SYSTEMS: THREE FOR ALL

###BREADCRUMB###

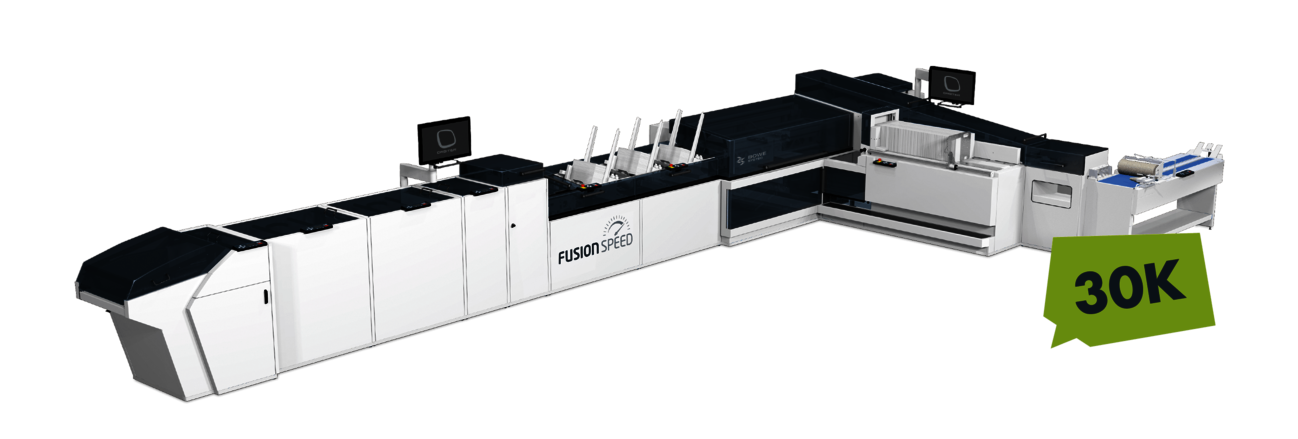

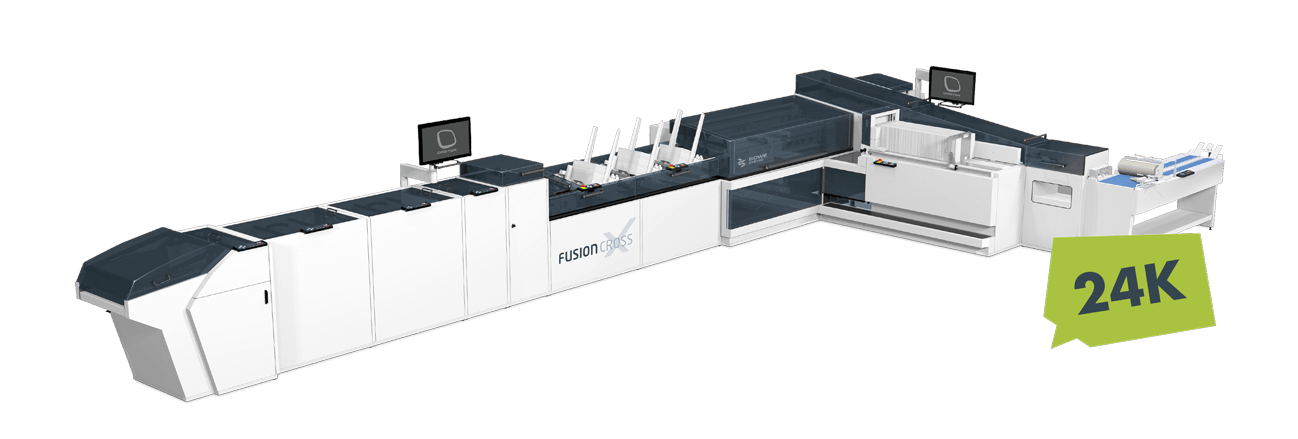

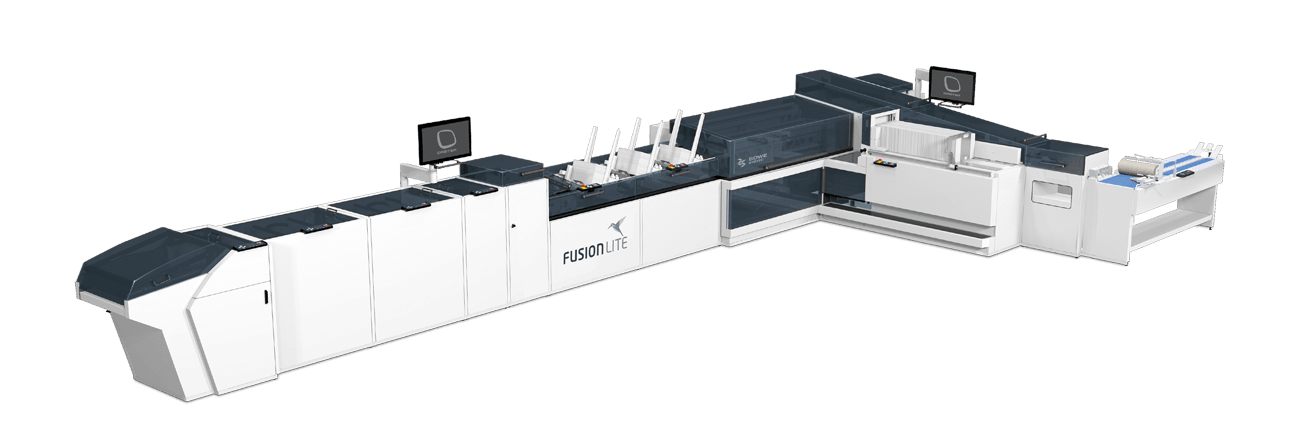

Offering both the pinnacle of inserting performance and genuine all-round capabilities, the three machines of the Fusion Series leave nothing to be desired when it comes to format or speed and flexibility. The Fusion Speed, Fusion Cross and Fusion Lite inserters process transactional mail and personalized direct mailings and much more with the highest degree of precision and stability, are outstanding in their performance, and can handle both small and large batches.

The Fusion Cross is a flexible multi-format inserter that processes envelopes from B6+ to B4 and 7 3/4 to Flats and enclosures weighing up to 1 kg at a maximum speed of up to 24,000 insertions per hour. Anyone looking for a jack of all trades will find this one is the master of them all. The Fusion Speed can handle formats from B6+ to B5 and 7 3/4 to 6 x 9 at speeds of up to 30,000 insertions per hour and really lives up to its name. Numerous automation options open up the possibility of higher output, yet lower staffing requirements. The Fusion Lite offers top of the range technology at a particularly attractive price. Capable of up to 16,000 envelopes per hour, it completes the trio. It, too, uses the Flow-Principle and can handle the complete range of formats from B6+ to B4 and #7 3/4 to Flats, whilst leaving nothing to be desired when it comes to processing enclosures. All BOWE SYSTEC inserting machines owe their capabilities to their unique Flow-Principle inserting technology, which reduces halts to an absolute minimum and delivers the highest net output in the industry and a smooth inserting process. In combination with smart and intuitive BOWE Cockpit control software, it is also possible to process large numbers of small jobs virtually seamlessly and without down times. Inserting taken to a new level. The Fusion Series: the only inserter your mail production center will need from now on.

9G INSERTERS: PROCESS ADVERTISING & TRANSACTIONAL MAIL SECURELY AND RAPIDLY

###BREADCRUMB###

Energy efficiency and environmental friendliness are features of the 9G family of inserters. At the entry-level there is the high-speed 9G Basic, which is particularly well suited to jobs involving the processing of a small number of sheets. This compact powerhouse has a footprint of just 12 m2. The document inserter offers all the capabilities of a high-performance system despite its small footprint and delivers high performance at an unbeatable price. For its part, the flexible and modular 9G inserting system even takes high-volume transactional mail in its stride and is capable of peak speeds of up to 26,000 envelopes per hour. Inserting systems for any requirement in the transactional segment.

INTUITIVE MACHINE CONTROL & NETWORKED PRODUCTION

###BREADCRUMB###

BOWE Cockpit control software app allows the intuitive control and simple setup of our inserting systems. Complex programming procedures are a thing of the past, job changeovers can be completed within the minimum of time. The intuitive software keeps training requirements to a minimum, reduces downtimes and errors, and so allows the systems to be used more efficiently. Even the processing of individual small jobs can be turned into profitable, high-speed production. The app BOWE One offers a host of central, cross-system functions in the inserting sector. Enjoy the advantages of networked production and optimize your processes across systems and sites using precise, real-time data. Database-driven production guarantees seamless item tracking with maximum integrity. Interfacing to a Warehouse Management System as well as the integration of further automation technologies also opens up entirely new possibilities for the automation and enhanced efficiency of your production center.

FIRST CLASS PRODUCTS, FIRST CLASS SERVICE

###BREADCRUMB###

MAKING SURE EVERYTHING IN YOUR MAIL PRODUCTION CENTER RUNS SMOOTHLY. ANY TIME, ANY PLACE.

WE ARE WORLDWIDE BY YOUR SIDE

###BREADCRUMB###

T +49 821 5702-0

F +49 821 5702-234

send email

Contact us at our Headquarters in Augsburg or find your local BOWE contact in your country.