INSERTING SYSTEM

FUSION CROSS

###BREADCRUMB###

ONE SYSTEM FOR ALL APPLICATIONS.

- ONE INSERTING SYSTEM FOR ALL APPLICATIONS

- BROADEST FORMAT SPECTRUM

- HIGHEST ENCLOSURE FLEXIBILITY

- PATENTED FLOW-PRINCIPLE

- FAST CHANGEOVERS IN ONLY 90 SECONDS

- FAST, SECURE, STABLE, GENTLE ON MATERIAL

- INTUITIVE OPERATION

A SINGLE INSERTING SYSTEM FOR ALL APPLICATIONS

###BREADCRUMB###

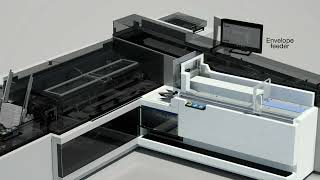

With the introduction of Fusion Cross, a new era in inserting technology has begun. No other inserting system is as flexible or handles such a wide spectrum of envelope formats and filling thicknesses at such high speed, while still being reliable and gentle on the material. Together with the high degree of automation and the accompanying fast job changeovers, the Fusion Series' Fusion Cross is the perfect machine for every inserting application – whether in transaction or direct mail. With this intuitively operated high-performance inserting system, you are fully equipped for all requirements in a mail production center – now and in the future.

Discover our

Fusion Cross

###BREADCRUMB###

TECHNICAL DATA

###BREADCRUMB###

| ENVELOPE FORMATS | B6+ – B4 | #7 3/4 – Flats |

| MAX. SPEED | 24,000 ENV/H |

| MAX. ENCLOSURE THICKNESS | 15 MM | 0.59" |

| NUMBER OF CHANNELS | ≥ 1 CHANNEL |

| MAX. FILLING THICKNESS | 15 MM | 0.59" |

High

throughput

Maximum flexibility

Broadest format filling thickness spectrum

True all-rounder

UNIQUE FLOW-PRINCIPLE INSERTING TECHNIQUE

###BREADCRUMB###

With the “Flow-Principle”, BOWE SYSTEC has introduced a completely new approach to inserting, letting the whole production process flow smoothly. Inserting speed is reduced by a factor of 4.5 to allow for more time during the inserting procedure. Even at the highest speeds, this groundbreaking new inserting principle ensures especially reliable processing – gentle on both materials and machine. The advantages are clear:

- Stops are reduced to a minimum

- A stable and reliable processing process is ensured

- Allows for secure processing of the broadest spectrum of formats and even difficult enclosures

The required integrity is ensured by intelligent system control and monitoring along with continuous document tracking throughout the production process via the connection to our powerful software.

PLANNING, CONSULTING AND SUPPORT: CUSTOMIZED SOLUTIONS THAT EXACTLY FIT TO YOUR NEEDS

###BREADCRUMB###

ONE TYPE OF INSERTER TO PROCESS ALL KINDS OF FORMATS

###BREADCRUMB###

No other high-performance inserting system is as flexible and processes as broad a spectrum of envelope formats as Fusion Cross. This revolutionary system can handle both small formats like B6+ or #7 3/4, as well as large formats like C4, B4 or Flats without any difficulty. Even at high speeds, Fusion Cross can meet all the diverse requirements of the production mail center perfectly. Quick set-up times and easy changeover between different formats round off the Fusion Cross portfolio.

DIRECT MAIL OR TRANSACTIONAL PREPARED FOR ALL FUTURE TASKS

###BREADCRUMB###

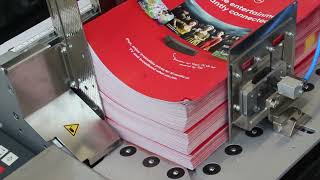

Fusion Cross bridges the gap between transactional and direct mail: high-integrity processing of important documents and non-standard enclosures while retaining the highest productivity. Thanks to its unique inserting principle and the variety of enclosure feeders, this inserting system can process an extraordinarily broad range of enclosures with the highest possible output. No material is too difficult for the Fusion Cross and its enclosure feeders. No matter if it is thin, thick, rigid, smooth, folded or unfolded: this multi-format inserter processes a wide range of enclosures up to 15 mm and 1 kg absolutely reliably. Furthermore, with its open device carrier concept, which allows for free configuration and easy changeover between various enclosure feeders, the inserting system also offers the highest possible flexibility.

UNIVERSAL MODULARITY THROUGHOUT THE INSERTING PROCESSES

###BREADCRUMB###

Transaction and direct mail service providers today wish for greater automation as this offers new growth opportunities. Integrate and automate upstream or downstream work steps that have been carried out separately and manually until now, with the help of further BOWE SYSTEC technologies that are available for the Fusion Cross inserting system. High-performance input channels in flexible configurations for the most diverse assembling, folding or stapling applications, modules for variable color envelope printing, sorting functions or integrated post box systems expand the functions of the inserting system, and reduce the need for additional special machines and staff.

INTELLIGENT SOFTWARE FOR THE PRODUCTION OF TOMORROW

###BREADCRUMB###

INTUITIVE SYSTEM OPERATION

###BREADCRUMB###

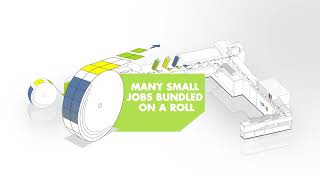

The intuitive control software BOWE Cockpit makes it easier to prepare and process the orders, automatically carries out format changeovers, and significantly shortens the changeover times. A comprehensive management information system allows an exact production analysis, right up to monitoring every letter processed. And all of that with a simple and intuitive operating interface, based on smartphone apps. Fusion Cross inserting systems can be interconnected. Job and material descriptions are thus available at the same time on other machines of this type, the systems automatically adapted to the respective applications. The Small Batch Processing software also has a rationalizing effect. It allows many small jobs to be bundled on a roll of paper and to be processed with high efficiency.

A HIGH-PERFORMANCE INSERTING SYSTEM FOR ALL APPLICATIONS

###BREADCRUMB###

Fusion Cross fulfills all the requirements crucial to the success of modern mail production with its uncompromising performance characteristics, a unique inserting principle, and high flexibility in handling enclosures. Inserting system Fusion Cross performs almost every application required in production mailing centers and allows full operational control – irrespective of the size of the production site and number of systems. This allows a single Fusion Cross system to displace multiple existing inserters. The benefits speak for themselves:

- Can process all transactional or direct mail applications on a single system

- With its uncompromising performance, Fusion Cross can replace multiple other systems

- Less inserting systems are needed to achieve the same or even higher output

- Reduction of service and maintenance costs

- Minimal training requirement

- Short changeover times and reliable production

- Maximum efficiency

Make your mail production center fit for the future and discover the Fusion Series’ Fusion Cross. With its inserting technology of the future it’s the only one inserting machine you’ll need from now on.

MODULAR TO THE CORE

###BREADCRUMB###

The totally modular approach to the design of Fusion inserters and their range of options make highly automated production possible.

*Some features listed may not be available for all systems types.

High performance begins with the input channel

###BREADCRUMB###

Whether cut-sheet or continuous processing, whether single or multi- channel input, the well-thought-out paper feed of BOWE SYSTEC infeed channels allows them to fulfil varied mail production center requirements and to deliver maximum efficiency. Top performance is guaranteed by the lightning fast, high-performance input channel with integrated Flow Booster.

Insurance policy processing made simple

###BREADCRUMB###

Every day, output centers produce hundreds of thousands of letters and policies for insurance companies. These may consist of multiple different documents and enclosures and need to be sent out to the customer within 24 hours. Our solution for high volume policy production is the high-speed assembling and stitching module.

High enclosure flexibility guarantees ability to handle future applications

###BREADCRUMB###

The inserting principle and the range of enclosure feeders means that Fusion Series inserters can handle a broad spectrum of enclosures. The open device carrier concept allows a flexible use of feeders, whilst the enclosure Autoloader increases efficiency still further and reduces the strain on operators at high production speeds.

The perfect fold at top speed

###BREADCRUMB###

The BOWE SYSTEC pocket folding module means that Fusion inserters deliver perfect folds even at full speed. Versions with two or four folding pockets can fold up to eight or up to 16 sheets simultaneously. Whether it be Z-, C-, single or double parallel fold, Fusion inserters have the right solution for every application.

Brilliant printed results with EPOD envelope printing

###BREADCRUMB###

Envelope Print On Demand (EPOD) allows logos or individual marketing messages to be printed directly on the envelope in full color. This opens up completely new possibi- lities for catching the eye as well as boosting efficiency. As an added bonus, pre-printed envelopes no longer need to be stored, which simplifies internal logistics.

BOXIT postal tray system: efficient mail logistics

###BREADCRUMB###

BOXIT is a smart system for automatically filling postal trays. It is a standard feature of all Fusion Speed systems and an optional feature for other inserting systems. BOXIT takes the envelopes filled by the inserter and automatically deposits them in the appropriate post box. Optionally, robots can prepare the filled postal trays for onward transport.

Videos &

Pictures

###BREADCRUMB###

WE ARE WORLDWIDE BY YOUR SIDE

###BREADCRUMB###

T +49 821 5702-0

F +49 821 5702-234

send email

Contact us at our Headquarters in Augsburg or find your local BOWE contact in your country.