INSERTING SYSTEM

9G

###BREADCRUMB###

TOP INSERTING PERFORMANCE THROUGH EXPERIENCE.

- IDEAL FOR TRANSACTIONAL MAIL

- HIGHLY FLEXIBLE

- FAST, SECURE, EFFICIENT

- STABLE PROCESSING USING PNEUMATIC & SERVO TECHNOLOGIES

- ECO-FRIENDLY, ENERGY-EFFICIENCT

THE NINTH GENERATION REPRESENTS PERFECTION

###BREADCRUMB###

Since introducing the first generation of today's 9G in 1976, BOWE SYSTEC has continuously updated and improved the inserter’s concept. For the design of the ninth generation, the focus was on energy efficiency and the security of the production process. In line with these market requirements, the ninth generation is the most eco-friendly system in its class and features more than 90 technical improvements. Amid all these innovations, 9G retains its successful qualities, like gentle handling through vertical transport and the introduction of pneumatic and servo technologies, minimal set-up times through fully automated job changeovers and modularity – and all this while maintaining the highest level of integrity and a throughput of up to 26,000 or 22,000 envelopes per hour.

discover our

9G

###BREADCRUMB###

TECHNICAL DATA

###BREADCRUMB###

| ENVELOPE FORMATS | C6 – C5 | #7 3/4 – 6 X 9 |

| MAX. PERFORMANCE | 26,000 ENV/H |

| MAX. ENCLOSURE THICKNESS | 1.8 MM | 0.08" |

| NO. OF CHANNELS | ≥ 1 CHANNEL |

| MAX. FILLING THICKNESS | 7 MM | 0.28" |

HIGH THROUGHPUT

MAXIMUM INTEGRITY

TOTAL FLEXIBILITY & FULLY MODULAR

MARKET-PROVEN & MATURE TECHNOLOGY

THE 9G INSERTING CONCEPT

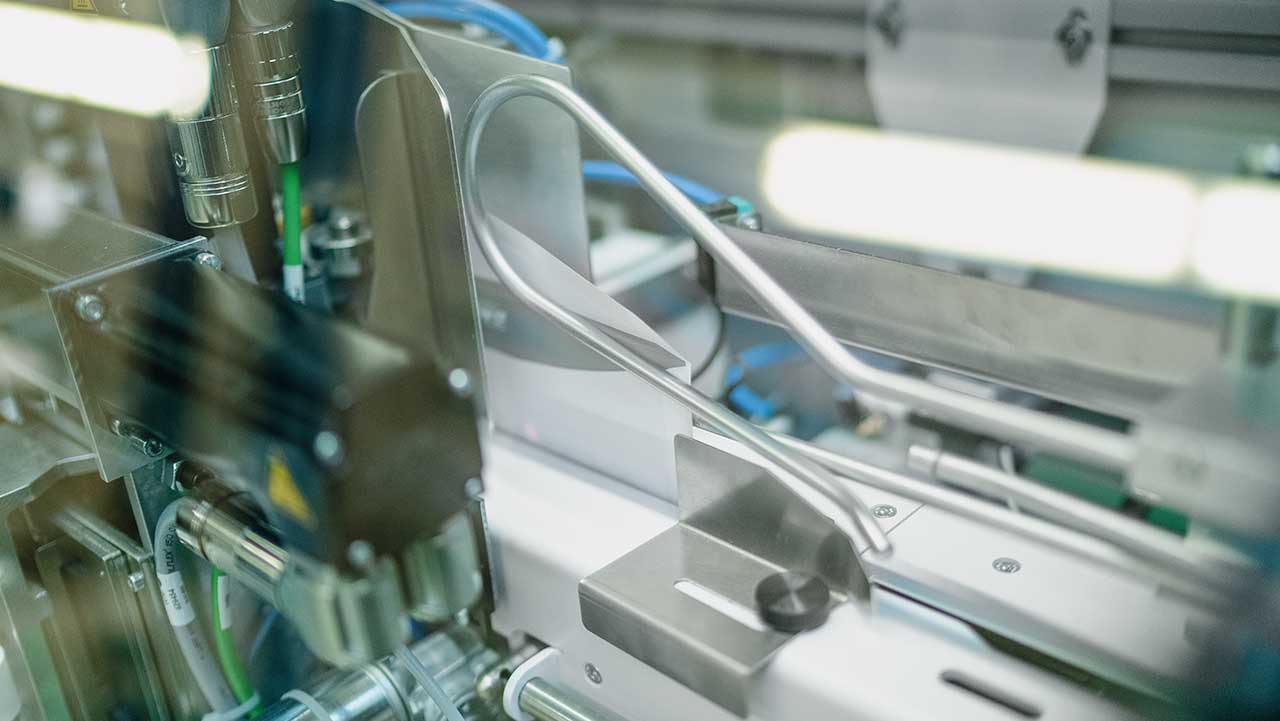

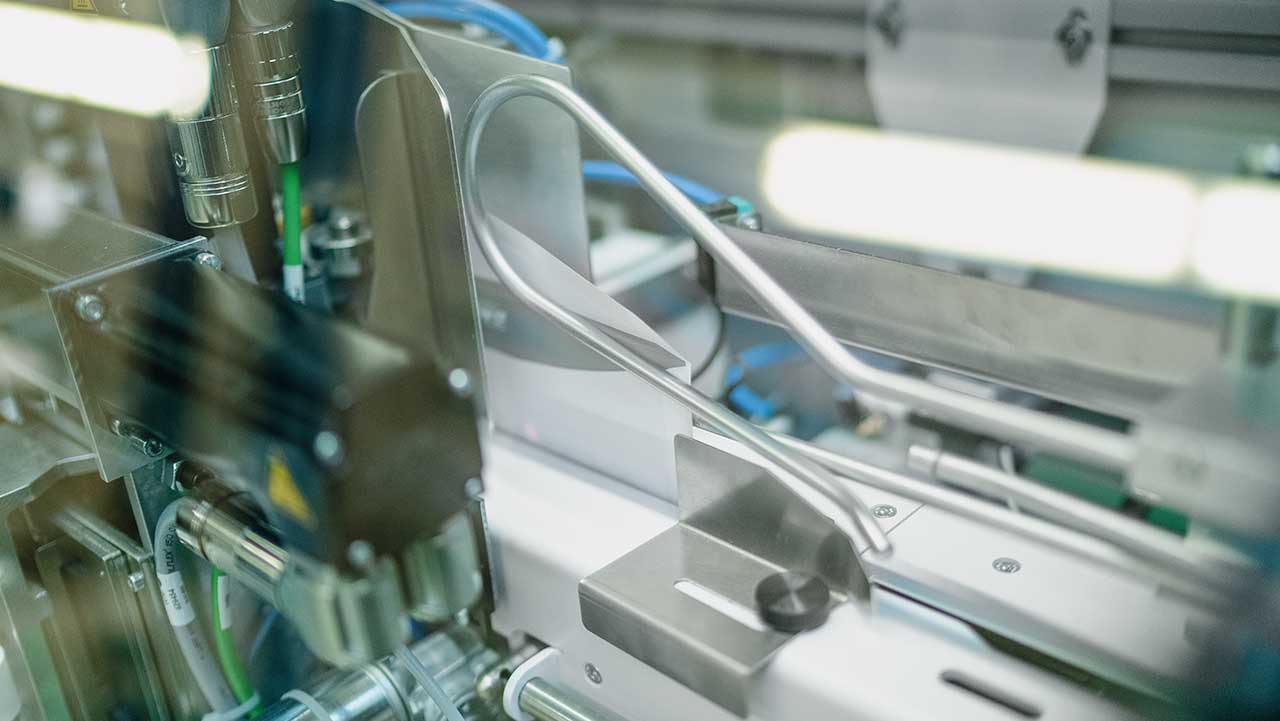

FAST, GENTLE AND INTELLIGENT PROCESSING

###BREADCRUMB###

Vertical transport of materials ensures secure guiding and fast, precise handling of documents. This process reduces not only wear and tear on the material, but also on the machine, guaranteeing reliable performance in continuous operation. Pneumatic and servo technologies increase the precision and security of processing. For the 9G inserter, the transport speeds have been harmonized. This improves continuity of the process and enables the production of high print volumes within the shortest time. Highest integrity is achieved by utilizing sensors to locate and identify each and every document within the system.

A SOPHISTICATED INSERTING SYSTEM

AT TWO DIFFERENT SPEEDS

9G offers integrity, flexibility and productivity at the highest level for high volume mail processing. From document infeed to enclosure handling and post-processing, all production steps are perfectly integrated. This remarkable system is available in two performance classes: At a performance of up to 26,000 envelopes per hour, the 9G 26k is perfect for single-channel applications and high-volume jobs with low page count per envelope. The competitively priced 9G 22k with a performance of up to 22,000 envelopes per hour is ideal for complex single- and multi-channel applications or high-volume jobs. In case mailroom requirements change, upgrading the 9G 22k to 26k is easy.

PLANNING, CONSULTING AND SUPPORT: CUSTOMIZED SOLUTIONS THAT EXACTLY FIT TO YOUR NEEDS

###BREADCRUMB###

NO RISK, NO FUN? NOT WITH US!

###BREADCRUMB###

When sending official documents that may contain sensitive, personal information, data protection and integrity during processing become even more important. 9G Series inserting systems do not just offer exceptional performance, their use of the latest software enables them to fulfil the most stringent integrity and data protection requirements. Reading units and sensors ensure seamless tracking of items throughout the entire production process. Play safe with us!

TAILOR-MADE INSERTING SOLUTIONS FOR EVERY REQUIREMENT

###BREADCRUMB###

The requirements for the mailroom continue to become more and more complex and the demand for more flexible machines continues to grow. That is why the 9G shows its versatility in every way. Beginning with both compact and competitively priced basic version up to sophisticated high-performance systems, the 9G inserting system provides the perfect solution for any application and for every mail production center. The modularity of the 9G also allows the adaptation of the systems to the floor space available and existing processing procedures. Take advantage of our years of experience as a mailroom specialist and discover the flexible inserting system 9G guaranteeing secure and fast processing of your documents – we are pleased to provide advice!

MODULAR TO THE CORE

###BREADCRUMB###

The totally modular approach to the design of 9G Series inserters and their range of options make highly automated production possible.

*Some features listed may not be available for all systems types.

High performance begins with the input channel

###BREADCRUMB###

Whether cut-sheet or continuous processing – input channels for different performance ranges make the 9G Series perfect systems to have by your side. The high-speed infeed channel is capable of feeding up to 100,000 sheets/h* to guarantee top performance. 9G systems are also multi-channel ready with patented auto-synchronization.

Flexible

sequencing

###BREADCRUMB###

Requirements in a mail production center are becoming ever more complex and the need for machines to be flexible keeps on growing. The versatility of the 9G begins with its infeed, where the newly developed sequencer allows the system to be effortlessly adapted to existing printing and mailroom processes.

Tornado creates a stir in any mailroom

###BREADCRUMB###

The Tornado unwinder for continuous envelope infeed promises significant efficiency improvements for the mailroom. It can automatically feed a continuous flow of C5, C6/5, DL as well as 6 x 9 and #10 envelopes into the inserter over a prolonged period of time, reducing operator workload, and for long runs with standard envelopes it is virtually a must-have.

Brilliant printed results with EPOD envelope printing

###BREADCRUMB###

Envelope Print On Demand (EPOD) allows logos or individual marketing messages to be printed directly on the envelope in full color. This opens up completely new possibi- lities for catching the eye as well as boosting efficiency. As an added bonus, pre-printed envelopes no longer need to be stored, which simplifies internal logistics.

BOXIT postal tray system: efficient mail logistics

###BREADCRUMB###

BOXIT is a smart system for automatically filling postal trays. It is a standard feature of all Fusion Speed systems and an optional feature for other inserting systems. BOXIT takes the envelopes filled by the inserter and automatically deposits them in the appropriate post box. Optionally, robots can prepare the filled postal trays for onward transport.

INTELLIGENT SOFTWARE FOR THE PRODUCTION OF TOMORROW

###BREADCRUMB###

BOWE IQ

MACHINE CONTROL

###BREADCRUMB###

9G Series systems are centrally controlled by means of BOWE IQ mailroom software. The modern design of the clearly structured and easy to understand user interface speeds up both job programming and operation. BOWE control software also enhances reporting and serves as the foundation for increased system productivity.

BOWE ONE

Mailroom Management

###BREADCRUMB###

BOWE One offers a host of central, cross-system inserting functions. Enjoy the benefits of networked production and optimize your processes at the system and the site level on the basis of precise, real-time data. Database controlled production also allows seamless tracking of items throughout the production process. 100% integrity guaranteed.

Videos &

Pictures

###BREADCRUMB###

WE ARE WORLDWIDE BY YOUR SIDE

###BREADCRUMB###

T +49 821 5702-0

F +49 821 5702-234

send email

Contact us at our Headquarters in Augsburg or find your local BOWE contact in your country.