INSERTING MACHINE

FUSION SPEED

###BREADCRUMB###

MAXIMUM THROUGHOUT, MINIMUM STOPS.

- HIGH PROCESSING VOLUMES

- MAXIMUM SYSTEM EFFICIENCY

- HIGHEST NET OUTPUT IN THE INDUSTRY

- PATENTED FLOW-PRINCIPLE

- CONSISTENT AUTOMATION

- INTUITIVE CONTROL & NETWORK-READY

INSERTING TECHNOLOGY OF THE FUTURE

###BREADCRUMB###

Complex jobs, a wide range of formats and enclosures, those infamous "last minute" orders; anyone who wants to survive and thrive in this demanding business really has to have inserting machine technology that keeps pace with the ever-increasing requirements. A high level of automation, stable and reliable processing, together with high net output are the order of the day. That’s why BOWE SYSTEC developed the Fusion Series – an inserting machine that is ideal for mailing and transactional users. Now and in the future.

Discover our

Fusion Speed

###BREADCRUMB###

TECHNICAL DATA

###BREADCRUMB###

| ENVELOPE FORMATS | B6+ – B5 | #7 3/4 – 6 x 9 |

| MAX. SPEED | 30,000 env/h |

| MAX. ENCLOSURE THICKNESS | 15 MM | 0.59" |

| NUMBER OF CHANNELS | 1 channel |

| MAX. FILLING THICKNESS | 15 MM | 0.59" |

High throughput

Fastest & most efficient system on the market

Highest net output in the industry

Your route to the automated mailroom

FUSION SPEED INSERTING MACHINE:

MAXIMUM PROCESSING VOLUMES, MINIMUM OF STOPS

###BREADCRUMB###

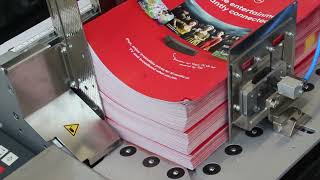

The Fusion Series’ Fusion Speed offers top speeds of up to 30,000 envelopes per hour and really lives up to its name. With a maximum speed of 30,000 envelopes per hour, the Fusion Speed is undoubtedly one of the fastest and most efficient inserting machine on the market. The inserting machine can handle formats from B6+ to B5 and #7 3/4 to 6 x 9, leaves nothing to be desired in terms of enclosure processing and its performance parameters mean that it delivers the highest net output in the industry. It will pay for itself in no time at all.

INSERTING

NON-STOP

All the Fusion Series inserting machines owe their capabilities to their unique Flow-Principle inserting technology, in which the filling speed is slowed down by a factor of 4.5 so that the actual inserting process is allowed more time. This means a variety of envelope formats and complex enclosures can be handled non-stop in an extremely stable and reliable production flow. The combination of this unique technology and a smart software package turns these inserting machines into intelligent systems. Top of the range inserting, with just one platform for all applications.

PLANNING, CONSULTING AND SUPPORT: CUSTOMIZED SOLUTIONS THAT EXACTLY FIT TO YOUR NEEDS

###BREADCRUMB###

CONSISTENT AUTOMATION

###BREADCRUMB###

In order to allow its operators to keep pace with this level of performance and to give full rein to the Fusion Speed’s capabilities, the inserting machine comes with a high level of automation and paves the way to the automated mail production center. So, for example, the BOXIT postal tray system can be integrated. BOXIT takes filled envelopes and automatically places them in mail bins. Numerous other options for automating up- or downstream processes, as well as ones that have been carried out manually up until now expand the function of this system and also smooth the way to higher output – but with fewer staff. The integration of conveyors and autonomous vehicles (AGVs) from BOWE INTRALOGISTICS or BOWE IQ Warehouse Management Systems complement the automation concept perfectly.

SMART, SMARTER, FUSION INSERTING MACHINES!

###BREADCRUMB###

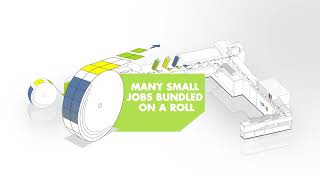

However, productivity and flexibility are not just a question of speed. The Fusion Speed and its sister inserting machines, Fusion Cross and Fusion Lite, really come into their own in combination with smart software. Intuitive BOWE Cockpit control software from our software division BOWE IQ greatly simplifies the preparation and execution of jobs. Format changes are handled automatically, changeover and therefore down times are cut to a minimum, errors avoided. Small batch processing software allows multiple small jobs to be processed seamlessly and non-stop off the roll. These smart systems can be networked with each other and controlled intuitively, and it is this level of intelligence that paves the way to the automated yet highly flexible mail production center of tomorrow. The industry of tomorrow in the best sense!

FUSION SPEED: THE ONLY INSERTING MACHINE YOU’LL NEED

###BREADCRUMB###

The Fusion Speed is the ideal inserting machine for anyone who doesn’t need to process large formats but wishes for maximum output with a minimum of staff. Advantages at a glance:

- One system platform for all applications

- Fastest and most efficient inserting machine on the market

- Highest net output in the industry

- Ideal for high processing volumes

- Broad application spectrum and high flexibility

- Consistent automation paves the way to the automated mail production center

- Smart & networked production

Make your mail production center fit for the future and discover the Fusion Series’ Fusion Speed. With its inserting technology of the future it’s the only one inserting machine you’ll need from now on.

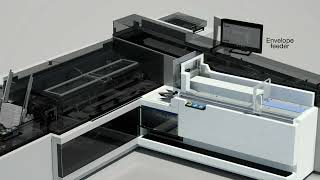

MODULAR TO THE CORE

###BREADCRUMB###

The totally modular approach to the design of Fusion inserters and their range of options make highly automated production possible.

*Some features listed may not be available for all systems types.

High performance begins with the input channel

###BREADCRUMB###

Whether cut-sheet or continuous processing, whether single or multi- channel input, the well-thought-out paper feed of BOWE SYSTEC infeed channels allows them to fulfil varied mail production center requirements and to deliver maximum efficiency. Top performance is guaranteed by the lightning fast, high-performance input channel with integrated Flow Booster.

Insurance policy processing made simple

###BREADCRUMB###

Every day, output centers produce hundreds of thousands of letters and policies for insurance companies. These may consist of multiple different documents and enclosures and need to be sent out to the customer within 24 hours. Our solution for high volume policy production is the high-speed assembling and stitching module.

High enclosure flexibility guarantees ability to handle future applications

###BREADCRUMB###

The inserting principle and the range of enclosure feeders means that Fusion Series inserters can handle a broad spectrum of enclosures. The open device carrier concept allows a flexible use of feeders, whilst the enclosure Autoloader increases efficiency still further and reduces the strain on operators at high production speeds.

The perfect fold at top speed

###BREADCRUMB###

The BOWE SYSTEC pocket folding module means that Fusion inserters deliver perfect folds even at full speed. Versions with two or four folding pockets can fold up to eight or up to 16 sheets simultaneously. Whether it be Z-, C-, single or double parallel fold, Fusion inserters have the right solution for every application.

Brilliant printed results with EPOD envelope printing

###BREADCRUMB###

Envelope Print On Demand (EPOD) allows logos or individual marketing messages to be printed directly on the envelope in full color. This opens up completely new possibi- lities for catching the eye as well as boosting efficiency. As an added bonus, pre-printed envelopes no longer need to be stored, which simplifies internal logistics.

BOXIT postal tray system: efficient mail logistics

###BREADCRUMB###

BOXIT is a smart system for automatically filling postal trays. It is a standard feature of all Fusion Speed systems and an optional feature for other inserting systems. BOXIT takes the envelopes filled by the inserter and automatically deposits them in the appropriate post box. Optionally, robots can prepare the filled postal trays for onward transport.

Videos &

Pictures

###BREADCRUMB###

WE ARE WORLDWIDE BY YOUR SIDE

###BREADCRUMB###

T +49 821 5702-0

F +49 821 5702-234

send email

Contact us at our Headquarters in Augsburg or find your local BOWE contact in your country.